In the competitive landscape of industrial manufacturing and printing, the difference between a good product and a great one often comes down to the finishing process. For decades, Ultraviolet (UV) technology has been a cornerstone of production lines, facilitating instant curing, coating, and bonding. However, simply having a UV system is no longer enough to guarantee a competitive edge. The industry has shifted toward optimized UV technology—systems engineered to deliver precise, consistent, and energy-efficient performance that far outstrips legacy equipment.

Understanding the mechanics behind these advancements reveals why manufacturers across sectors, from automotive to packaging, are upgrading their lines. It is not merely about drying ink or hardening a coating; it is about achieving a superior finish while reducing operational costs and energy consumption.

The Evolution Beyond Standard Curing

To appreciate the leap forward represented by optimized technology, one must first look at the limitations of traditional setups. Older UV systems often relied on brute force: high-energy output that generated significant heat and consumed vast amounts of electricity. While effective at curing, these systems were often inefficient. Much of the energy was lost as infrared heat rather than being converted into the useful UV energy required for the polymerization process.

Optimized UV technology changes this dynamic. It focuses on the entire system architecture—power supply, cooling, reflector geometry, and lamp design—to ensure that the maximum amount of energy reaches the substrate in the most efficient way possible. This holistic approach results in a curing process that is faster, cooler, and more reliable.

Precision Engineering and Spectral Output

The core of optimization lies in spectral matching. Different chemical formulations (links, coatings, and adhesives) react to specific wavelengths of UV light. A standard off-the-shelf UV curing lamp might provide a broad spectrum of light, but if a significant portion of that light doesn’t match the photoinitiators in the chemistry, energy is wasted.

Modern optimized systems are designed to deliver peak irradiance at the exact wavelengths required for the specific application. Whether utilizing doped mercury arc lamps or advanced UV LED arrays, these systems ensure that the energy output aligns perfectly with the chemical absorption profile. This results in a complete cure through the entire thickness of the material, preventing issues like surface tackiness or poor adhesion which can compromise product quality.

The Critical Role of Reflector Geometry

One of the most overlooked aspects of a UV system is the reflector. In a typical setup, only a fraction of the light emitted by the bulb travels directly to the product. The rest radiates outward in all directions. Without an optimized reflector, that energy is lost.

Superior performance is achieved through advanced reflector geometry. Engineers use computer-aided design to create reflectors that capture stray light and focus it into a concentrated band of energy on the substrate. This creates a higher peak intensity, which allows production lines to run faster without sacrificing cure quality. Furthermore, sophisticated coatings on these reflectors can absorb infrared heat while reflecting UV energy, helping to manage the thermal load on sensitive substrates like thin films or plastics.

Smart Power and Energy Efficiency

The era of the simple “on/off” switch is over. Optimized UV technology integrates intelligent power supplies that communicate directly with the production line. These electronic ballasts provide stepless dimming, meaning the UV output can ramp up or down automatically based on the speed of the conveyor.

If a line slows down, the UV output drops to match it, preventing burning or over-curing. If the line stops, the system can switch to a standby mode instantly. This level of control drastically reduces energy consumption. Users are no longer paying for full power when they only need 50%, nor are they wasting electricity keeping a system running hot during downtime.

This intelligence extends to stability. Traditional systems often suffer from voltage fluctuations that cause inconsistent UV output. Optimized power supplies condition the incoming power, ensuring a stable, constant output regardless of mains fluctuation. The result is a uniform finish on every single product, from the first batch of the morning to the last run of the night.

Thermal Management and Substrate Protection

Heat is the enemy of many modern manufacturing materials. As electronics become smaller and packaging materials become thinner and more eco-friendly, they become increasingly susceptible to heat damage.

Optimized UV systems tackle this through advanced thermal management. By utilizing “cold mirror” reflectors that absorb infrared energy and water-cooling systems that regulate the temperature of the lamp housing, these technologies direct pure UV energy to the substrate while diverting heat away. This capability opens the door to processing heat-sensitive materials that were previously impossible to cure with older, hotter UV systems.

Making the Switch for Future Growth

Adopting optimized UV technology is an investment in operational resilience. As environmental regulations tighten and energy costs fluctuate, the ability to do more with less becomes a critical survival metric. Systems that offer higher throughput with lower energy draw provide an immediate return on investment.

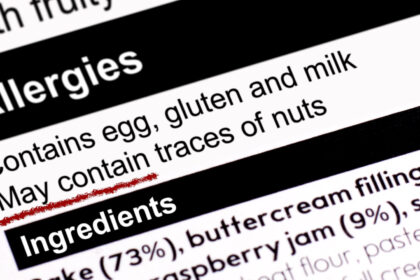

Moreover, quality assurance is non-negotiable. In high-stakes industries like medical device manufacturing or food packaging, an incomplete cure can lead to product failure or safety recalls. An optimized system provides the data and consistency needed to ensure compliance and maintain brand reputation.

Elevating Your Production Standards

The shift toward optimized UV technology represents a maturation of the industry. It moves away from the “more power is better” mindset toward a philosophy of precision and efficiency. By focusing on how energy is generated, focused, and controlled, manufacturers can unlock superior performance that drives growth.

Whether it is through replacing a single UV curing lamp with a more efficient model or overhauling an entire production line with intelligent power supplies and advanced reflectors, the path to better manufacturing is clear. Optimization is not just a buzzword; it is the standard for modern industrial performance.